Euresys frame grabbers enable high-speed sorting of coffee berries

Euresys frame grabbers enable high-speed sorting of coffee berries

Xeltron high-speed inspection machines rely on Grablink Duo Camera Link frame grabbers

Xeltron high-speed inspection machines rely on Grablink Duo Camera Link frame grabbers to combine accuracy with throughput.

Inspecting agricultural products is a special challenge in the vision industry. Natural products are, by essence, not standardized and may vary in shape, color, ripeness, moisture, etc.

Xeltron, a Costa-Rica based machine manufacturer specializing in color sorting machines for coffee, berries, beans, and nuts, was facing exactly this challenge. By developing the company’s own proprietary image processing hardware and software, Xeltron was able to design a dry product sorting machine that achieved an accuracy as high as 99.9%. The system was relying on a patented optical electronic analyzer fed by vertical rollers or chutes.

- 99,9%

sorting accuracy

- 4tons per hour

per chute

- 16tons per hour

on the XLT series

Small produce, big challenge

“While this unprecedented accuracy was valued by customers with the highest quality standards, the throughput was not sufficient and the footprint was too large to satisfy the needs of most mass-purchasers at an affordable cost,” explains Massoud Gougani, Project Manager at Xeltron.

To achieve a higher throughput, Xeltron decided to take a completely new approach: Instead of inspecting a stream of beans using individual optical analyzers, the company placed line scan cameras on both sides of the curtain, or stream, to capture a 360° view of each grain. This double-sided inspection enabled them to achieve higher accuracy at a much higher speed, allowing their XV series for dry product to handle larger volumes in a smaller footprint.

Differing from the horizontal conveyor belt sorters, Xeltron’s engineers designed the XLT series color sorters to inspect a flow of humid berries falling vertically like a continuous curtain using the same line scan cameras’ color analysis concept, eliminating the use of motors, rollers, roles, and conveyor belts and their high maintenance cost.

High-resolution and high-speed image acquisition

The new concept required a high-speed image acquisition and processing pipeline. Xeltron turned to a high-end Japanese camera manufacturer for high-speed line-scan cameras and selected a HD RGB with Camera Link interface and 4K pixels resolution.

For the frame grabber, Euresys was recommended because of the long-lasting partnership Euresys had with the camera manufacturer.

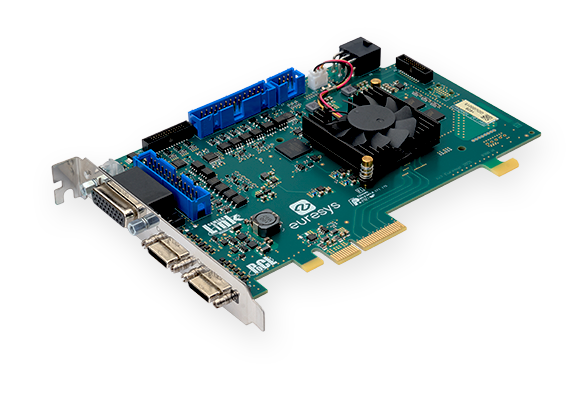

Xeltron first selected Euresys’ Grablink DualBase Camera Link grabber to operate the two cameras in a Camera Link base configuration. Euresys then recommended the latest generation Grablink Duo boards and provided support to Xeltron for a smooth replacement.

The Euresys Grablink Duo features two Camera Link ports for one full- or two base-configuration Camera Link cameras. Its PCIe Gen 2 x 4 bus ensures high image data throughput to Xeltron’s proprietary host processor.

Xeltron’s proprietary color and size grading software performs image processing in real-time and triggers high-speed valves to eliminate non-conforming berries or beans and foreign matter from the flow.

The results of these design efforts are Xeltron’s XLT wet coffee berries and XV dry product sorting machine series. Thanks to state-of-the-art technology, the XLT and XV series achieve 95% to 98% accuracy at an average throughput of four (4) metric tons per hour per chute and up to sixteen (16) tons per hour on the XLT series, and from one (1) to eighteen (18) tons per hour on the XV series, depending on the screened product.

Collaboration key to success

“With the new XLT model, we are able to meet bulk purchasers’ quality and cost requirements and allow our customers to maximize yield”, says project manager Gougani. “We are not only fully satisfied with Euresys’ frame grabber itself, but also with the technical support provided during the integration phase. This close collaboration to meet our requirements was key to the success of the project.”